Remote Monitoring & Digitization: Fuelling the Future of Oil and Gas

“Digitization is the new lubricant for the future of the oil and gas industry’s upstream sector.” – Strategy & report by PwC.

In the current landscape of the oilfield industry, the need for innovation is not just desirable—it’s imperative for survival. Companies are under increasing pressure to optimize operations, reduce environmental impact, and stay ahead in a fiercely competitive marketplace. The twin engines driving this transformation:

- Advanced digital technologies and,

- Robust commitment to sustainability

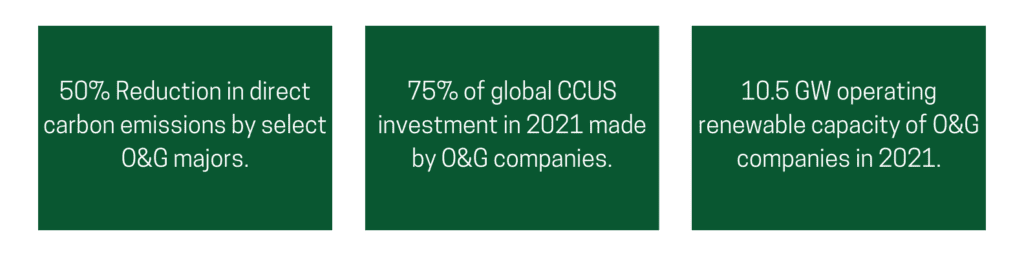

And it comes as no surprise that the commitment to a better environment is moving to the top of O & G company initiatives.

Deloitte Insights – Striking a Balance Report – August 2022

We will examine two pivotal oilfield technology solutions side by side from 2 perspectives: when to use together and when to combine for optimal value. We will dissect the established app, SCADA, renowned for its breadth and depth and introduce a new contender, the WatchDog platform, which is innovative for its low-cost, swift-deployment, and app package that eliminates the need for heavy upfront infrastructure.

This discussion aims to unpack the features and benefits of each, leaving the practical applicability in your capable hands.

SCADA

Supervisory Control and Data Acquisition: Oilfield SCADA Software

SCADA systems are the industrial world’s technological linchpins, providing critical data acquisition and supervisory control across vast and remote locations. Think of it as an industrious digital hub enabling producers to streamline processes and synthesize data to empower informed decision-making. SCADA, a stalwart in the oil and gas sector, shines in its role as an operator’s digital ally, boasting a user-friendly interface, tailor-made monitoring, and control applications essential for precise equipment control and daily operations.

While we could delve into the complexities of its programming and configuration capabilities, we’ll focus on its substantial scope and its robust communication with remote telemetry units (RTUs) and programmable logic controllers (PLCs). Owing to its power, SCADA’s sophistication comes with a significant cost—both financial and schedule. Designing and implementing a rollout requires significant time and money.

Most of our prospects don’t know that WatchDog can complement an already invested SCADA system. How? WatchDog requires zero infrastructure and can be deployed in minutes.

The WatchDog (and SCADA)

The Evolution of Oilfield Monitoring

A persistent challenge the industry has faced is the ability to fully blanket or equip the operational infrastructure in the field. Balancing cost and complexity with effective outcomes has proven to be a challenge. For a long time, producers have grappled with how to and justify the economics of remote oilfield monitoring for producing wells. The complexity and robustness of most SCADA packages conflicts with the benefit and ROI for widely distributed and lower-producing field assets.

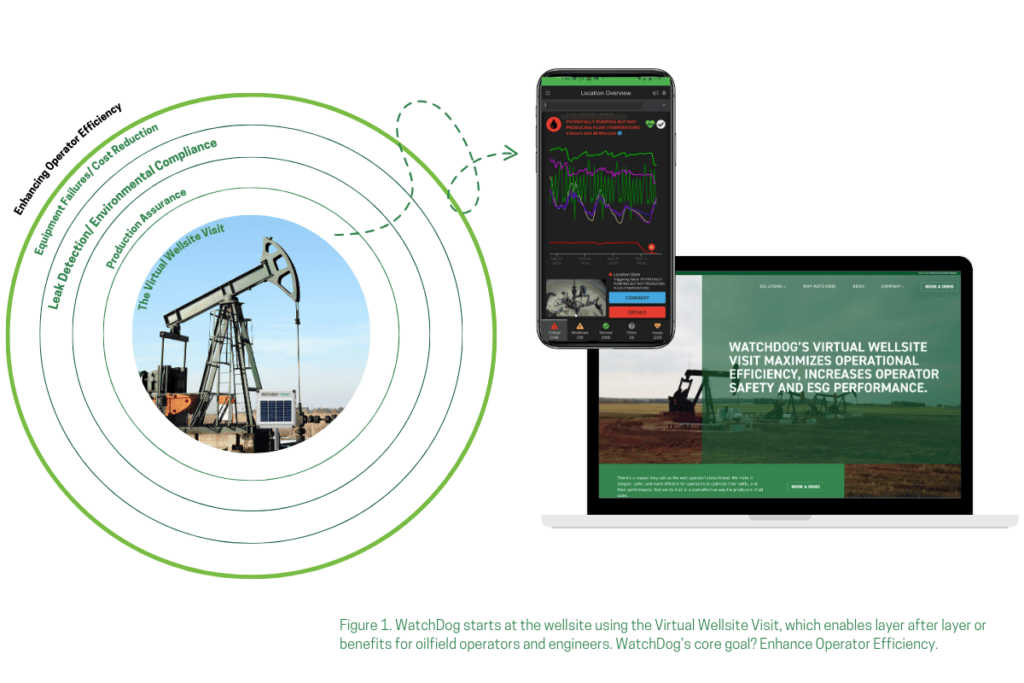

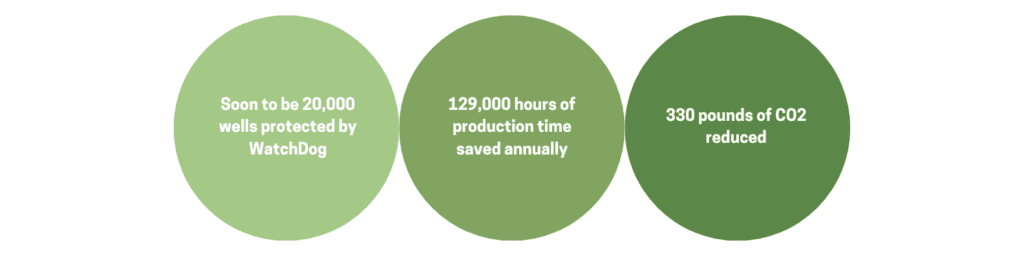

Enter the WatchDog platform by Advanced Flow Technologies Inc. (AFTI): a nimble addition to the traditional SCADA framework. For over ten years, AFTI has been at the vanguard, melding camera technology, artificial intelligence, and patented algorithms into an industry-leading platform. Often integrating with existing SCADA systems or other automation tools, WatchDog has proven to be the “cherry on top” for enhancing operational efficiency across nearly 20,000 field sites.

WatchDog distinguishes itself with a low-cost, robust, and user-friendly installation, promising a swift ROI. Its array of advantages—like boosting production, reducing equipment failures, saving operator time, enhancing safety, and mitigating environmental issues—is remarkable. Notably, WatchDog achieves this with existing systems without the need for supplementary infrastructure, configuration, or coding. The cost savings are dramatic compared to traditional SCADA investments, an eye-opener for many in the industry. For a decade, WatchDog’s philosophy has been that “just enough data,” refined through intelligent and patented algorithms, can adequately inform operational decisions. The goal of any surveillance system is to inform and drive action, the WatchDog platform excels in optimizing data for input to operational action.,

Today, AFTI collaborates with some of North America’s largest producers—many of whom are SCADA veterans—to fine-tune production and lessen environmental impacts.

If we journeyed through the exciting world of oil and gas remote operations, we’d find three maturity levels to explore (plus recent environmental adjustments).

The Spectrum of Technological Progression

The journey through oil and gas remote operations reveals three progressive stages of maturity, each with its own set of technological advancements and environmental considerations.

- Remote Monitoring: At this level, real-time operational data takes center stage, linking distant field operations directly to headquarters. This isn’t just about operational oversight—it’s about gathering comprehensive insights on asset integrity, diagnostic analytics, performance tracking, and key performance indicators (KPIs).

- Remote Control: A step closer to autonomous operations, remote control involves centralized command centers that manage operations without direct human presence on-site. These centers are backed up by local field control units, providing a safety net in case of contingencies.

- Autonomous Operations: Although less common globally, this pinnacle of remote operations enables a fully autonomous operational model. Here, continuous closed-loop processes thrive, akin to an autonomous vehicle system, enhancing production optimization and emergency responsiveness.

Moreover, new policies are anticipated to expedite the shift towards clean energy…

Recent reports from Deloitte highlight a steady annual increase in clean energy investments by oil and gas entities since 2020, suggesting a more prominent role for these investments in future capital expenditure.

Features and Functionality: The App Showdown

Let’s break it down further and take a closer look at the standout functionalities of both apps.

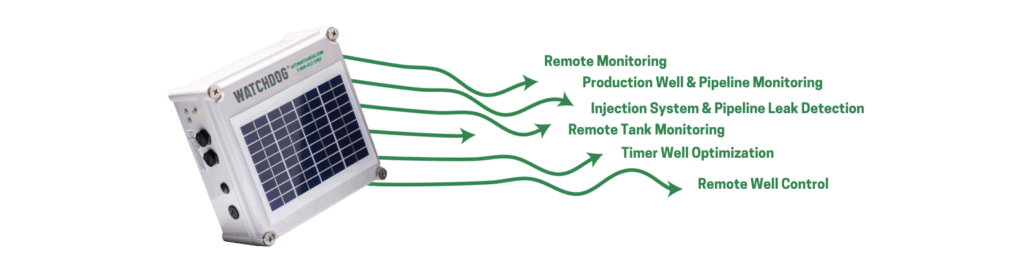

The WatchDog Approach

On the flip side, we have the WatchDog suite: a combination of hardware ingenuity and software simplicity. Its hallmark is its minimalism—a swift, simple, and direct approach to oilfield monitoring. Its deployment? WatchDog captures the true essence of plug-and-play. The hardware—a fusion of durable components, power supply, cellular communication, and essential sensor arrays—sets the stage for an unprecedented ease of installation.

Currently, the majority of industry focus is on the first two stages, but as AI solutions for the oilfield evolve, the third stage—Autonomous Operations—will increasingly come into play. For oil and gas projects to be viable, it is crucial to maintain low operational costs while improving production efficiencies. Herein lies the challenge and necessity of feature and benefit comparisons of existing technologies.

The SCADA Perspective

Let’s look at SCADA through the lens of reliability, integrity, and operational excellence. It’s a technology that’s become synonymous with comprehensive monitoring and precise control in the industrial sphere. The journey of SCADA from a simple data display to a complex network of automated operations is a testament to its adaptability and the ingenuity of its engineers.

SCADA systems play an integral role in various industries, offering a robust framework for industrial process control and the acquisition of real-time data from dispersed sites. In the oil and gas domain, SCADA is invaluable for its comprehensive features, including intuitive user interfaces, tailored monitoring, and critical operational applications. SCADA facilitates communication with remote telemetry units (RTUs) and programmable logic controllers (PLCs), granting operators remote oversight and data analytics capabilities crucial for efficient infrastructure management. Despite its extensive functionality, the main caveat of SCADA lies in its significant infrastructure investment and setup complexity.

Environmental and Economic Impact: A Comparative Analysis

In this era of environmental consciousness, the oil and gas industry’s carbon footprint has come under intense scrutiny. Each technological approach—whether the established SCADA or the insurgent WatchDog—must be weighed against its environmental impact and potential to drive sustainable operations. While SCADA systems have a comprehensive environmental monitoring capability, the WatchDog system’s swift alert mechanisms and potential for real-time mitigation of environmental risks could give it an edge for companies keen on minimizing their ecological impact promptly and effectively. Moreover, the economic argument for operational efficiency has never been stronger. While SCADA systems deliver wide-ranging functionalities, the investment involved is considerable. This is where the WatchDog system can appeal to budget-conscious enterprises that seek a balance between operational excellence and cost-effectiveness.

Even if you’re already heavily invested in SCADA, WatchDog is the “cherry on top” to existing systems. No infrastructure required.

Conclusion: Foraging the Future

As the industry stands at the crossroads of legacy systems and emerging technologies, the balance between investment and innovation becomes critical. Companies must weigh the long-standing dependability and broad capabilities of SCADA against the swift deployment, cost-effectiveness, and flexibility of the WatchDog solution. Each solution carries the potential to transform operations in unique ways, but the decision must align with the strategic goals, operational landscape, and environmental imperatives of the oil and gas industry. The path forward may be a hybrid model that leverages the strengths of both SCADA and WatchDog to foster a new standard in operational efficiency and environmental stewardship.